Reveal How Product Packaging Tools Repair Work Provider Job to Maintain Your Operations Running Smoothly

Product packaging devices fixing solutions are important for maintaining the efficiency of production lines. These solutions not just detect problems however also do necessary repair work to avoid costly downtimes. Recognizing just how these fixings job can substantially influence functional performance. Yet, lots of companies forget the indications that show when repairs are required. Checking out the subtleties of these services reveals important insights that can aid organizations stay affordable in a busy market.

Understanding the Importance of Packaging Devices Fixing

Product packaging equipment repair work plays a critical function in preserving operational effectiveness for services throughout different markets. The correct performance of packaging machinery is vital for ensuring that products are packaged precisely and securely, which directly impacts high quality control and customer satisfaction. When devices breakdowns, it can bring about manufacturing delays, increased downtime, and possible monetary losses - Packaging Equipment Repair Services. Routine upkeep and timely repair services help to reduce these risks, allowing companies to maintain productivity levels and stick to delivery schedules.Furthermore, competent service technicians can identify underlying issues before they intensify into considerable troubles, consequently expanding the life expectancy of the equipment. This aggressive method not just reduces fixing prices in the lengthy run but additionally boosts the general security of the workplace. By prioritizing product packaging equipment repair solutions, businesses can ensure that their procedures run efficiently, ultimately sustaining their development and competition out there

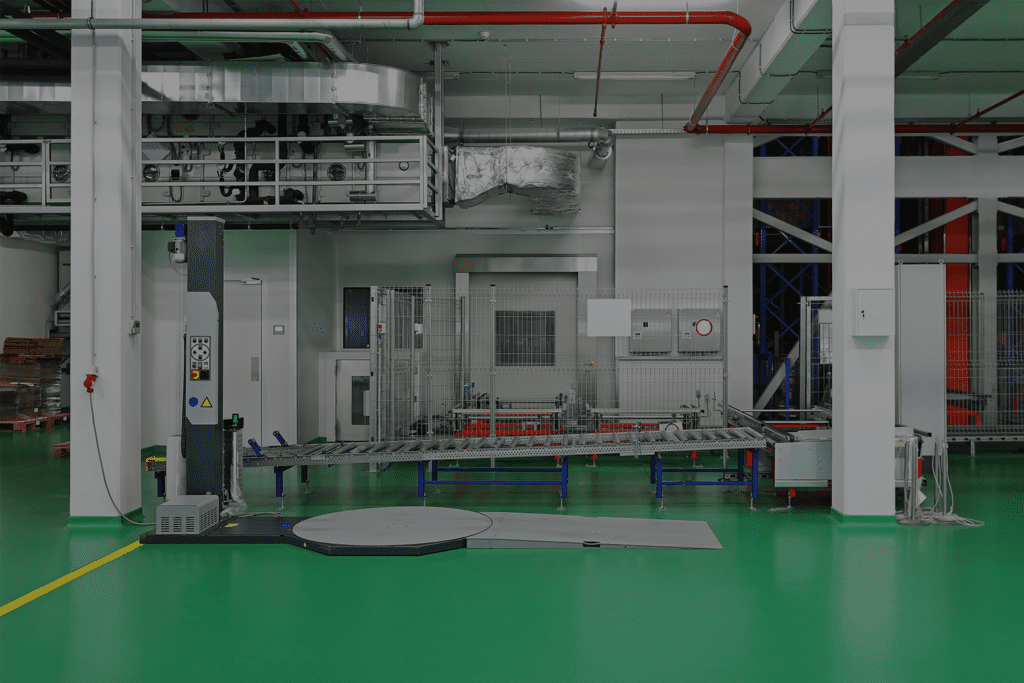

Usual Kinds Of Product Packaging Equipment and Their Functions

A varied variety of devices is utilized in the packaging process, each serving distinct functions to improve performance and product honesty. One usual kind is the filling equipment, which precisely dispenses liquids or solids right into containers, ensuring regular quantity. Sealing machines adhere to, using warm or pressure to secure packages and prevent contamination. Classifying equipments are additionally important, as they use item info and branding, which is necessary for compliance and customer recognition. Additionally, cartoning machines automate the procedure of putting items into boxes, enhancing product packaging operations. Stretch wrappers and diminish wrappers are utilized for palletizing items, providing security throughout storage and transportation. Examination systems ensure quality control by discovering issues or disparities in packaging. Each of these equipments plays an important duty in keeping an efficient process, lowering manual labor, and seeing to it that items reach customers in suitable problem.

Indicators That Your Product Packaging Equipment Needs Repair Service

When production effectiveness lowers or product high quality fails, it typically suggests that packaging tools requires attention. A number of signs can pinpoint the requirement for repair. Uncommon sounds, such as grinding or squealing, often suggest mechanical issues that could result in added damage. Constant jams or imbalances during operation can interrupt workflow and signal that parts are put on or malfunctioning. Furthermore, inconsistent packaging results-- such as poorly sealed bags or mislabeled products-- can suggest problems with the equipment's calibration or capability. A rise in downtime, calling for even more frequent troubleshooting, is an additional indication of underlying problems that require resolving. Visible wear and tear, like torn belts or rust, can jeopardize devices performance. Recognizing these signs early can protect against expensive disruptions and assure that packaging operations run smoothly and successfully.

The Role of Preventive Upkeep in Product Packaging Procedures

Effective preventative maintenance is crucial for making certain ideal performance in packaging operations, as it decreases the danger of devices failing and enhances general performance. By carrying out a structured maintenance routine, companies can identify potential problems prior to they escalate into considerable troubles. Normal examinations, lubrication, and element replacements are important components of this process, guaranteeing that makers operate at peak levels.Additionally, precautionary upkeep can bring about lowered downtime, allowing for continuous production flow. By resolving wear and tear proactively, organizations can expand the lifespan of their tools and stay clear of costly fixings. This strategy not only boosts productivity however additionally cultivates a safer working environment by decreasing the possibility of accidents brought on by malfunctioning machinery. Ultimately, a commitment to precautionary upkeep is a strategic investment that supports the long-term success and reliability of packaging operations, straightening with organizational goals for efficiency and productivity.

Emergency Situation Repair Work Services: When Time Is of the Significance

Just how promptly can a packaging procedure recoup from unexpected equipment failure? In such important circumstances, emergency situation repair services play a necessary duty. These solutions are created to react quickly, frequently within hours, making certain marginal downtime. Technicians are typically on-call and furnished with the required tools and components to attend to a range of devices malfunctions - Packaging Equipment Repair Services. This fast response is essential for keeping production routines and preventing pricey delays.Emergency repair solutions usually include a complete diagnostic process, allowing technicians to determine the source of the failing rapidly. When diagnosed, repair services can be executed effectively, bring back equipment capability. Additionally, numerous service providers offer 24/7 assistance, making sure that assistance is offered whenever an emergency occurs. By focusing on fast reaction and expert solution, product packaging operations can significantly mitigate the influence of unanticipated break downs, inevitably sustaining continuous performance and operational dependability

Choosing the Right Packaging Tools Repair Company

The Benefits of Regular Maintenance and Timely Repairs

Normal maintenance and timely repairs of product packaging devices offer significant advantages for services. These methods not only enhance tools longevity but likewise lower downtime imp source costs, resulting in enhanced functional efficiency. By focusing on maintenance, companies can assure smoother operations and better source management.

Enhanced Tools Durability

While numerous services concentrate on making best use of efficiency, overlooking regular maintenance and prompt repair services can bring about increased costs and equipment failures. Routine maintenance is necessary for extending the life expectancy of packaging tools (Packaging Equipment Repair Services). It permits drivers to recognize and address possible problems before they rise, thus maintaining the stability of the machinery. Timely repairs not only recover capability however likewise avoid damage that can result from long term neglect. By investing in consistent upkeep, organizations can assure that their devices runs at peak efficiency, decreasing the danger of break downs. Improved equipment longevity adds to cost financial savings in the future, as it decreases the requirement for regular substitutes and helps maintain a constant workflow, as a result try this web-site sustaining total functional effectiveness

Reduced Downtime Expenses

Reliable upkeep and prompt fixings greatly reduce downtime costs for businesses counting on product packaging equipment. When machinery experiences unanticipated malfunctions, the monetary effect can be significant, influencing manufacturing schedules and profit margins. Normal maintenance helps recognize prospective issues prior to they intensify, guaranteeing that tools operates successfully and constantly. By addressing minor repair work immediately, organizations can stop pricey interruptions and mitigate the threat of extensive downtime. This positive method not just sustains a stable operations yet additionally fosters a foreseeable operational budget. Inevitably, investing in upkeep and fixing services grows a durable production atmosphere, where services can maintain their competitive side, reduce monetary losses, and keep consumer fulfillment by delivering products promptly.

Enhanced Functional Performance

Prompt repairs and consistent maintenance play a pivotal role in enhancing operational effectiveness for companies using packaging tools. Regular upkeep guarantees that machines operate at peak levels, reducing the likelihood of malfunctions that can interrupt production processes. When equipment is properly maintained, it can operate extra dependably, causing boosted outcome and uniformity in item quality. Prompt repair services minimize the risk of comprehensive damages, which frequently results in expensive substitutes and expanded downtimes. By focusing on maintenance and fixing solutions, organizations can enhance their operations, ultimately causing price savings and improved performance. This aggressive approach not just prolongs the life expectancy of the equipment yet also fosters a more secure working setting, adding to general operational success.

Regularly Asked Concerns

Just How Quickly Can I Anticipate Packaging Devices Fixing Services to React?

The rate of response from packaging devices repair solutions can vary substantially. Normally, business aim to deal with immediate demands within hours, while less critical problems might take longer, depending on accessibility and the intricacy of the repair service needed.

Are Packaging Tools Repair Services Available for All Equipment Brands?

Packaging tools repair service services generally accommodate different machinery brand names. Accessibility might differ based on the supplier's competence and collaborations, making it essential for operators to verify compatibility with their particular devices before looking for help.

What Credentials Should Technicians Have for Product Packaging Tools Fixing?

Technicians focusing on packaging tools repair service commonly possess qualifications in mechanical design or relevant areas, comprehensive hands-on experience, and knowledge of certain machinery brand names, ensuring they can properly detect and solve numerous equipment issues.

How Can I Prevent Future Breakdowns After Repairs?

To avoid future malfunctions, regular maintenance schedules should be developed, driver training stressed, and tools surveillance carried out. These aggressive actions can significantly improve reliability and long life, reducing the possibility of functional disruptions and unanticipated repair services.

What Is the Average Price of Packaging Tools Fixing Providers?

The typical price of packaging devices repair work solutions varies substantially, usually varying from $100 to $1,500, relying on variables such as devices kind, complexity of the concern, and required components or labor for the repair. Product packaging devices repair solutions are important for keeping the effectiveness of production lines. Routine maintenance and prompt fixings of product packaging devices supply substantial benefits for organizations. Effective upkeep and prompt repair work substantially decrease downtime expenses for businesses relying on packaging devices. Timely fixings and regular upkeep play a critical role in enhancing functional effectiveness for services making use of packaging devices. Packaging equipment repair service solutions commonly provide to numerous equipment brand names.